A400 offers exceptional durability in harsh chemical environments, so it’s an excellent material for structural and containment applications in industries where chemical resistance is critical. It resists degradation in acetic acid concentrations ranging from 0.1% to 98%, and delivers long-term performance for structural and containment applications thanks to its powerful strengths that range between 5,000 to 9,000 psi. It also offers potential cost savings through reduced maintenance and longer service life. Moreover, it has a neutral and decent finish like traditional concrete.

A400 offers advanced performance in aggressive environments, faster strength development, and a lower environmental footprint. For instance, it has an amazing durability under thermal stress, freeze-thaw cycles, and high-temperature conditions (up to 1,000°F), something that doesn’t happen with traditional cement concrete. Additionally, A400 geopolymer concrete offers versatile slumps (1–10 inches), no bleed water, fast finishing, and does not require curing compounds, making it a more resilient and sustainable alternative to traditional cement concrete in demanding applications.

While the initial material cost of A400 geopolymer concrete may be higher than traditional cement mixes, its long-term cost-effectiveness can outweigh the upfront investment. Keep in mind that A400 is a specialized, high-performance product, so its per-unit cost is generally higher than that of standard concrete. Not to mention that the high durability and chemical resistance of A400 contribute to a longer life cycle of infrastructure. For projects in corrosive or demanding environments, A400 often proves to be the more economical choice over time.

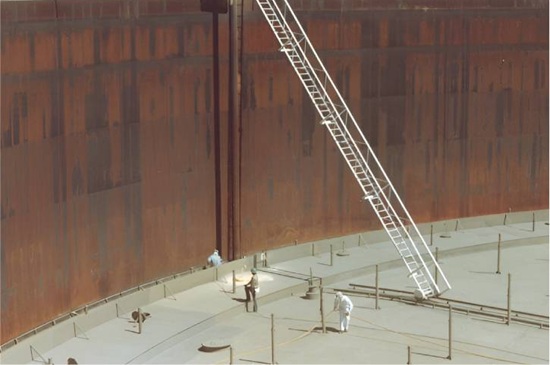

A400 geopolymer concrete is made for exceptional durability and chemical resistance, which extends its service life and reduces its maintenance compared to traditional cement concrete. Many structures made with A400 can last several decades with minimal maintenance, particularly in harsh environments like chemical containment, drainage systems, and industrial facilities. Its resistance to acetic acid (up to 98%), chlorides, sulfates, solvents, and freeze-thaw cycles helps prevent common issues like surface erosion, cracking, or corrosion of embedded metal components, making it long-lasting compared to other solutions.

Yes, A400 geopolymer concrete is well-suited for indoor and outdoor applications due to its robust physical properties and environmental adaptability. It resists thermal shock and does not degrade in freeze-thaw cycles, and unlike some surface coatings or materials, A400 maintains its structural integrity under direct sunlight and moisture exposure without needing sealants or curing compounds. Additionally, you can use it in vertical, horizontal, or self-leveling applications. It’s also suitable for foundations, walls, drain systems, masonry mortar, and floor overlays.