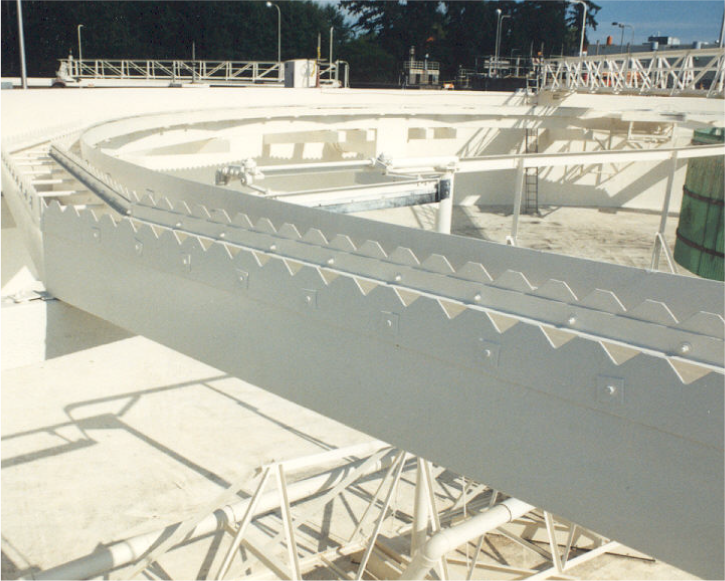

EXP Novolac Ceramic Lining Features

- Outstanding Chemical & Thermal Resistance

- Very Good Resistance To Moderate Abrasion

- Excellent Fluid Flow Characteristics

- Long-Term Flexibility & Durability

- High Resistance To Cavitation Damage

- Strong Resistance To Scaling Effects